Emergency collision repair facilities prioritize safety through meticulous equipment and tool inspections, ensuring personal protective gear is in good condition and critical tools like welders and sandblasters function properly according to industry standards. Before starting any work, detailed hazard assessments uncover potential risks, including hidden damage from storms like hail, which requires specialized auto maintenance techniques for effective hail damage repair. Technicians thoroughly inspect all repair tools, checking for wear, calibrating precision equipment, and validating tool alignment to minimize errors and maximize safety during emergency repairs.

In the critical minutes following a vehicle crash, emergency collision repair facilities play a pivotal role in ensuring driver and passenger safety. This article delves into the essential safety checks that underpin these specialized workshops. From mandatory gear inspections to rigorous hazard assessments and thorough tool audits, we explore the meticulous protocols keeping everyone safe. Discover how these measures not only safeguard occupants but also guarantee effective, efficient collision repair.

- Essential Safety Gear and Equipment Check

- Rigid Protocol for Hazard Assessment

- Comprehensive Inspection of Repair Tools

Essential Safety Gear and Equipment Check

In any emergency collision repair facility, ensuring the safety of personnel and equipment is paramount. Before beginning any restoration process, a thorough check of essential safety gear and equipment is non-negotiable. This includes inspecting personal protective equipment (PPE) such as gloves, eye protection, and respirators to guarantee they are in good condition and fit properly.

Additionally, mechanics should verify the functionality of critical tools and machinery specific to car bodywork and auto collision center operations. This involves checking welders for proper calibration, examining sandblasters for obstructions or damage, and ensuring power tools are maintained and up-to-date with safety standards for car paint services. These measures collectively contribute to creating a secure environment, enabling efficient and effective emergency collision repair processes.

Rigid Protocol for Hazard Assessment

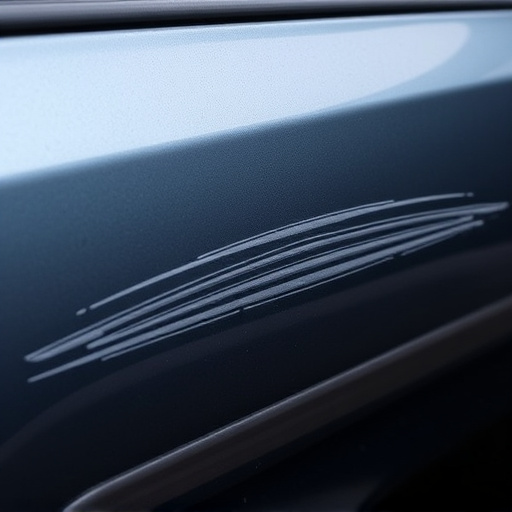

In emergency collision repair facilities, a rigid protocol for hazard assessment is non-negotiable. Before any work begins, thorough inspections are conducted to identify and mitigate potential risks. This meticulous process involves evaluating structural integrity, detecting hidden damage often obscured by dents or crumpled metal, and assessing hazardous materials like leaking fluids or compromised gas tanks. Every step is documented, ensuring a clear understanding of the scope of repair and potential challenges, which is crucial for the safety of both workers and subsequent vehicle owners.

The protocol encompasses not just physical risks but also environmental considerations, especially in areas prone to extreme weather conditions. Protecting against future damage, particularly from hail storms that can cause extensive hail damage repair, requires implementing robust measures. This includes securing fragile parts, using specialized auto maintenance tools designed for delicate operations, and ensuring proper vehicle paint repair techniques to maintain aesthetic value and structural integrity. Such protocols are the backbone of reliable emergency collision repair services.

Comprehensive Inspection of Repair Tools

In emergency collision repair facilities, one of the critical aspects of ensuring safety and high-quality work involves a thorough inspection of all repair tools. Before any car bodywork services or hail damage repair commence, technicians must conduct a comprehensive check to verify the functionality and condition of their equipment. This includes checking for any signs of wear and tear, as well as calibrating tools designed for precision tasks like paintless dent repair.

The process involves meticulous attention to detail, ensuring that every tool meets industry standards. For instance, inspection criteria may include examining welders for proper settings, testing paint applicators for consistency, and validating the alignment of jigs used in body replacement. This rigorous examination is pivotal in minimizing errors and maximizing safety during emergency situations where quick, reliable repairs are paramount.

In ensuring the highest standards in emergency collision repair facilities, rigorous safety checks are paramount. From essential gear inspections to comprehensive tool assessments, each step plays a vital role in creating a secure environment for both workers and vehicles. By adhering to strict protocols, these facilities can deliver quality repairs while maintaining a robust safety net, ultimately fostering trust among clients seeking emergency collision repair services.